Factory Tested

It takes longer to build units right, but we can confirm they’ve been built to the toughest standards.

Everything starts with the quality and durability of the materials that make up our units. We begin with an Acrylume sheet steel that’s coated with a clear organic resin surface treatment for excellent corrosion resistance in a salt fog environment. Any metal that’s in contact with water like our condenser and evaporator and exterior fasteners are all built out of stainless steel. Our units are closed-loop systems, meaning, we don’t allow any ingress, air from the outside to come inside the cabinet. For this reason, every one of our condenser coils is coated with a dipped Modine Luvata E-Coat (https://modinecoatings.com/electrofin-e-coat-process/) to extend the life against salt fog allowing our units to operate in some of the most extreme environments. Our esthetic cover is a powder-coated 5052 marine grade aluminum alloy.

Motors are a critical component of every air conditioner and we go to the extra expense to source the best. Rosenberg motors are engineered in Germany and manufactured in France with excellent distribution in the USA. Rosenberg fans have a high IP rating that protects against dust and water to add life to the equipment.

When space allows, we use a rotary compressor because they historically last longer and are more energy-efficient. Our TXV’s are exclusively Danfoss because they are the only TXV manufacturer that uses a stainless steel outside and inside copper blend for durability.

Downtime is not an option on critical telecommunications infrastructure. Units need to be able to operate in a wide range of temperatures and operate 24/7. We’re proud to be certified for use on AT&T cabinets.

Our units are designed and built around GR47 and to meet or exceed NEMA 4 tested and certified by UL with NEMA 4x (stainless steel cabinet) as an available option.

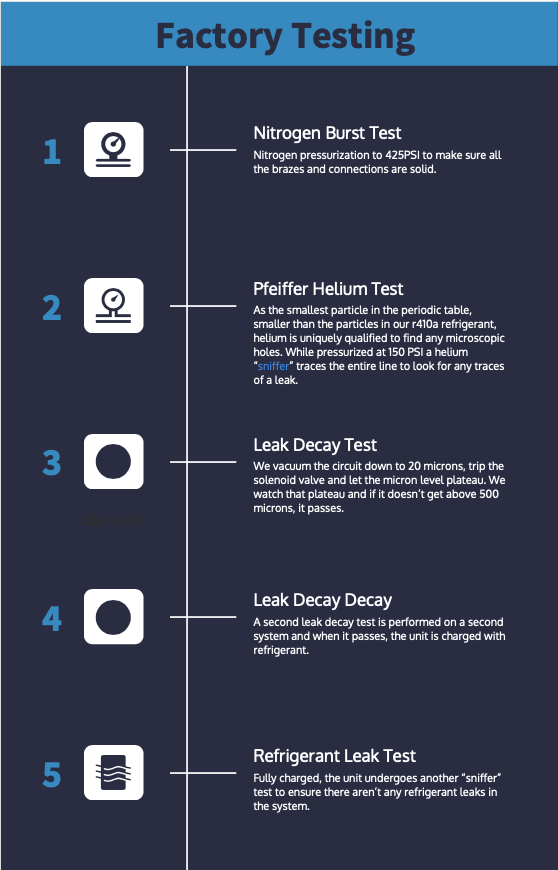

As the lifeblood of an air conditioner, we go great lengths to make sure the systems are sealed, is durable and reliable. Every unit undergoes an extensive testing and retesting process while it goes down the assembly line. Each unit is tested with:

- Nitrogen Burst Test - Nitrogen pressurization to 425PSI to make sure all the brazes and connections are solid.

- Pfeiffer Helium Test - As the smallest particle in the periodic table, smaller than the particles in our r410a refrigerant, helium is uniquely qualified to find any microscopic holes. While pressurized at 150 PSI a helium “sniffer” traces the entire line to look for any traces of a leak.

- Leak Decay Test - We vacuum the circuit down to 20 microns, trip the solenoid valve and let the micron level plateau. We watch that plateau and if it doesn’t get above 500 microns, it passes.

- Leak Decay Decay - A second leak decay test is performed on a second system and when it passes, the unit is charged with refrigerant.

- Refrigerant Leak Test - Fully charged, the unit undergoes another “sniffer” test to ensure there aren’t any refrigerant leaks in the system.

Each unit has a “Traveler” (accompanying paperwork) that goes with the unit and when it’s handed off to the next station, the previous tests are verified with new eyeballs to ensure they’re accurate. All the data collected on the traveler is tested against data and averages in our system by a Quality Supervisor that reviews it to make sure everything falls in line where it should be.

Compressor

Compressor

Height

Height